The other day I was in the kitchen when I heard a loud shriek followed by the distinctive clattering sound of something going terribly awry in our master bathroom. Rushing in, I found Sweetie holding one of three the mirrored doors to our medicine cabinet / vanity. The various potions, elixirs, and items of mystery that ladies use to get ready for their day were scattered about the counter top. The bottom hinge hardware had sheared off when she opened the cabinet and the door launched at her face, causing the calamity. She was not pleased.

The mirror didn't break, so at least I was pleased, even if she wasn't.

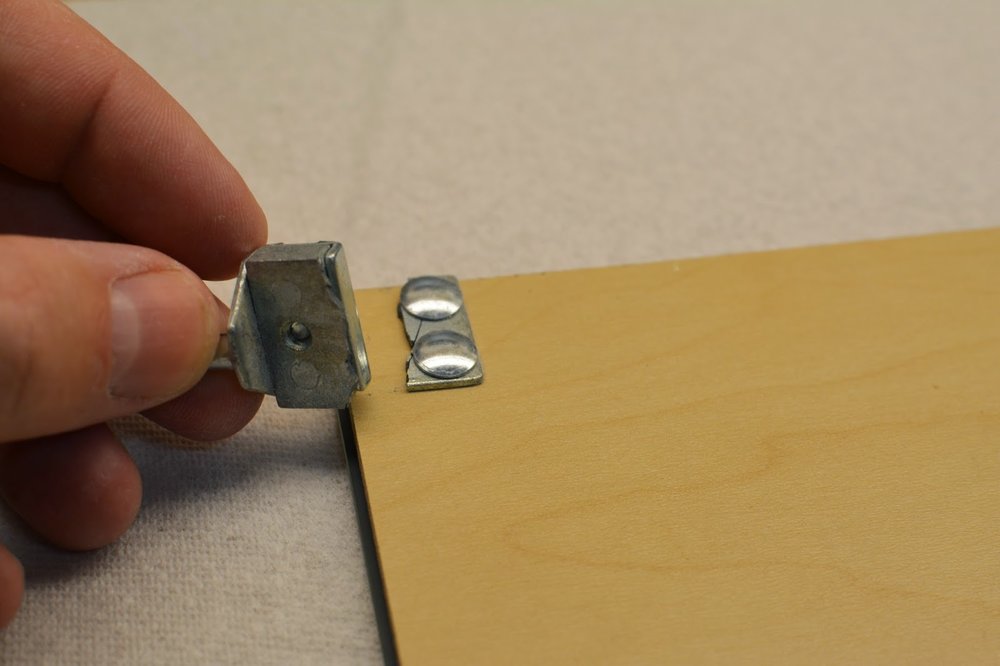

It's supposed to look like the photo below. The two circular things are fasteners (rivets(?)) that attach the hinge, through the wood backing that the mirror is adhered to. The hinge itself is an adjustable piece of hardware with a pin pivoting in a hole in the face frame. It looks like there's just too much stress on the cheap, cast metal piece.

This hinge in 100% non-broken condition, in its native habitat.

Fix-It Time!

Out to the workshop, the whole door goes. Every DIY minded homeowner knows and has holy trinity of repair materials on hand: duct tape, WD-40, and J-B Weld. This is a perfect job for J-B Weld. If you haven't tried it (because you've been stranded on an island in the south pacific DIY'ing your escape raft), prepare for awesomeness. If you have tried it, I know you'll keep reading, because you love the stuff too.

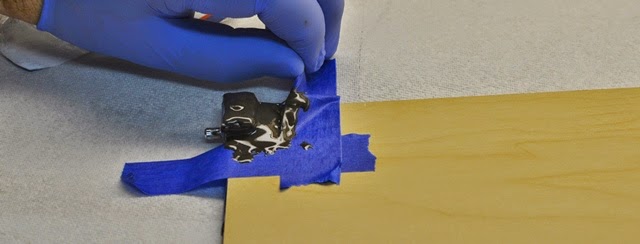

I laid the mirror on the bench, face down on some paper towels for protection. I decided to mask the area for a little neater finish and to protect the glass. It was also a chance to crack open the first roll of tape from the collection that ECHOTape sent me to play with.

ECHOTape has been around for over 40 years, but they've just started reaching out to the DIY market.

With the area cleaned and masked off, I deployed the JB Weld. For this application, I'm using their fast cure version, J-B Quick. Since it's a two-part epoxy, I started with the A component, which they labeled with the bad-ass name, "Steel". Note, I'm wearing the very bad-ass rubber gloves, because I don't want to get icky hands. I just used a scrap piece of cardboard.

The faint scent makes me think it's what peanuts mixed in motor oil would smell like, ...delicious!

Intrepid readers will have probably unraveled the foreshadowing clues I've cleverly laid out, using words like "two-part" and "A component". That's right, the second part is next; I'm creatively calling it "B". They call it "Hardener". It takes an equal sized schmear of Hardener to make the magic happen.

"Squiiiiiiirt...."

- J-B Weld Hardener

Mix it up thoroughly.

A popsicle stick makes a perfect, disposable stir-stick ... and get to work quick,... because it's JB Quick.

This stuff cures in 4 minutes. Plenty of time. I spread it on the mirror back and buttered the hinge too.

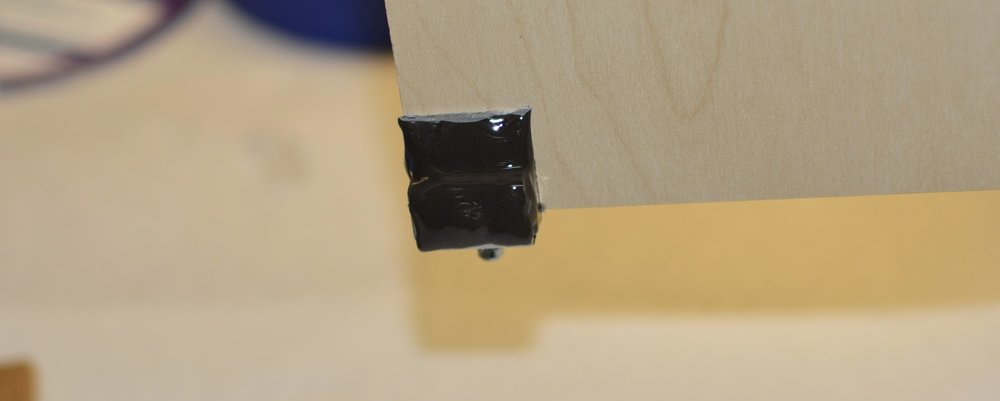

Since there's not much of a connection, I chose to encase the hinge back too. This thing is not going to break again. After about two minutes, I peeled of the masking tape while the epoxy was still soft.

I gave it a quick edge with an X-Acto knife. Done.

It's going to work perfectly. It's ready to hang, stronger than before.

I know this because, I'd fixed another hinge in the same cabinet over two years ago. It's still hanging.

Obviously, I didn't mask this one off.

Piece of cake eh? The stories of J-B Weld are legendary, repaired engine blocks and stuff like that. This is a non-sponsored post, I'm just a fanboy. You can get it at your local retailers like home centers, hardware stores, auto parts stores, some grocery stores or on Amazon.com.

IMPORTANT 2020 UPDATE: Do not attach the top and bottom hinges of the same mirror at the same time! Check out the comments section below. At the time I did the repairs, I had not had two hinges broken simultaneously.

Then it happened. It happened to other readers as well. If you fix both the top and bottom hinges so permanently as I have, you will never get the mirror reinstalled. You have to do it in such a way that you can still access the screw plate. Instructions on how I did it are in the comments.