I've been working on a hallway organizer furniture project for over two years now. Other, more pressing, projects keep pulling me away, but this is the one I fall back to putter on, when I have time.

As part of my challenge to clean up all the loose ends around here, I'm attacking the project with renewed effort. To get back in action, I need to make four drawer fronts.

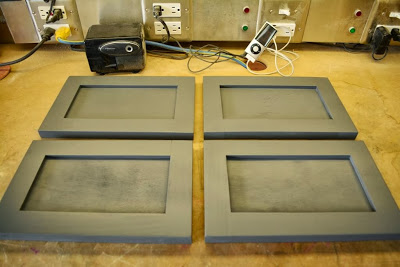

Initially, I was going with flat, recessed fronts. I even have them cut to size and sanded. The problem is, they simply look too plain. I wanted something a little more interesting.

As part of my challenge to clean up all the loose ends around here, I'm attacking the project with renewed effort. To get back in action, I need to make four drawer fronts.

Initially, I was going with flat, recessed fronts. I even have them cut to size and sanded. The problem is, they simply look too plain. I wanted something a little more interesting.

|

| Plain, like Saltines without the salt. Boring. |

Eventually, we hope to redo the kitchen with shaker style doors. I decided to take a crack at them for this project.

Now, if you actually want to do it properly, check out John's video from Our Home From Scratch. He has a great video on making Shaker doors properly, with tongue and groove assembly. Unfortunately, I don't have a dado (wide cut) blade for the table saw and my test attempts with my narrow kerf blade were tedious and gave less than great results. The normal router route won't work either; I don't have a router table or the proper bits. So, I'm not going to do it properly.

I've come up with my own quick and easy method. I think it's going to work.

I'm using poplar, since it's affordable, durable and easy to work with. To save time ("quick"), I purchased 1 ½ " x ¾" stock to make the stiles (vertical) and rails (horizontal) rather than ripping boards on the table saw. I used my big, Sliding Compound Miter Saw which made it an operation of absolute sawdust-spewing joy, but it could be easily done with a miter box and saw

which made it an operation of absolute sawdust-spewing joy, but it could be easily done with a miter box and saw or whatever other precision cutting methods your evil brain can devise. I mass-produced the cuts, using a stop block clamped to the fence for repetitive precision in my pieces. I was done in minutes.

or whatever other precision cutting methods your evil brain can devise. I mass-produced the cuts, using a stop block clamped to the fence for repetitive precision in my pieces. I was done in minutes.

|

| An operation of absolute sawdust-spewing joy. |

Quick tip: When I have the tool set up and am making precise, repetitive cuts, I often make several extra pieces, if I have enough wood. It saves heartache later when, I inevitably pull some lame-brained move and screw up a piece (...which I did do).

Here's where I take a weird turn, away from conventional construction methods. I routed a "rabbet" in the back side of each piece. A rabbet is a like a dado but is missing one of the shoulders. Its just a recessed notch. However, a rabbit is nothing like a dodo.

On woodworking joinery, extinct terrestrial avians, and common Lepus currpaeums:

I made a makeshift router table, probably not my finest safety moment,... definitely not my finest safety moment.

|

| Don't try this at home,... or at work,... or in a restaurant,... or in the shower. |

I made the cuts with a straight cutting bit, assembly line style, in several passes. One deep pass would be too deep and would get unwieldy (especially with my makeshift router table setup). There was no need to risk my fingers, trying rushing it through to quickly. The rails (horizontal) got a rabbet their whole length. The stiles got a rabbet that didn't show through on their ends.

|

| A freshly prepared rabbet. |

A glued butt joint might hold, but it wouldn't be exceptionally strong. Since our home is infested with rough-and-tumble children, I beefed it up with pocket holes and screws. I assembly lined all the pieces through the small, but mighty, Kreg Jr. Pocket Hole Jig  .

.

.

All the parts of the frame are complete. Time for assembly.

It was a standard glue-up. I use those cheap little welding flux brushes to spread it evenly.

I clamped it together temporarily and drove fine-thread, square drive screws from my Kreg Pocket-Hole Screw assortment . This step was done on my miter saw bench, because it's really flat. My MDF workbench top is a gouged, bumpy surface from years of spills and abuse.

. This step was done on my miter saw bench, because it's really flat. My MDF workbench top is a gouged, bumpy surface from years of spills and abuse.

I was pleased to have spare pieces; exuberance with the impact driver split the hell out of one.

Of course, speaking of spills,... flopping clamps, hammer taps, and an impact driver didn't agree with my fresh cup of coffee. Another reason to use the miter bench, the melamine coating is good for cleanups.

|

| I'm just glad I didn't knock my beloved Bad Ass coffee mug off the bench. |

Sweet success! The clamps came off as soon as the screws were in.

When they dried, I took them over to the disc sander to even out a little of the imperfections at the joints,...

|

| I only took a little meat off my pinkie knuckle. |

...to the random orbital sander to smooth out the face,...

...and finally to hand sanding, for final finish and to ease the sharp edges.

Once again, continuing my veering off the beaten track of proven assembly methods, I'm using a technique I found to install glass panels in frames. Instead of glass panels, I'm using 3/16 inch thick plywood panels.

Using a stiff putty knife, I drove glazing points into the frames, pinning the panels in place. The gap allows for expansion and contraction of the wood.

With all the glazing points in place, the panels are super tight.

They don't even move when I pry with the putty knife. I think (hope) it's going to hold. When it's attached to the drawer, there will be even more pressure pinning it in place.

Since it was a lovely December day, I took them out to the driveway to spray them with primer. I keep a couple big, leftover Styrofoam blocks around for this sort of thing. Propping the pieces up on toothpicks lets me get the edges.

It was at this point I realized three things:

- That is some seriously dark primer. Painting these things white will mean more coats.

- In my zeal to get the panels in, and concentrating on setting my camera, I had lost focus and installed a couple of the panels backwards, rough, un-sanded side out.

- Idiot.

With the backwards panels it's going to take some more filler and sanding to to get these rascals smoothed out for final coat. But I think I have a decent solution for Quick and Easy Shaker drawers. We'll see how they last in the long run. If I have to re-do them later, it's a simple swap out.

Followup notes.

- On quick and easy: It was both, quick and easy but the many outfit changes (I'm a Grand Master of wearing solid color T-shirts) and the changes in lighting in these photos betray me. I picked away at this over several days, stepping out in the garage for a few minutes here and there between doing other stuff.

- Before mass producing the four fronts, I used the old Norm Abram's New Yankee Workshop trick of building a first pre-production copy. I worked out the problems and played with the technique before committing to building all of them. You'll see this mystery prototype in the background. It's assembled without glue, just the screws, but it's holding tight.

|

| Eyeballing the prototype piece on the actual project. |

Simple, easy, and inexpensive. What do you think?