How to re-fill a flat tubeless tire, for wheel barrows, utility carts, lawn mowers, hand trucks, and etc.

Read MoreReplacing a Water Heater - New Energy Saving Features

The exciting tale of how I replaced a Water Heater and gained modern energy management features. Bonus - I replaced the supply valve too! Now with 100% more George Costanza.

Read MoreLiving Room Remodel: Glue-Down Showdown (Solid Wood Flooring)

Living Room Remodel: Episode 4 I’m laying solid wood planks down over concrete with the sloppiest adhesive ever conceived by man. It’s gonna be great!

Read MoreDIY Lamp Repair - A Fixing Stuff Adventure

|

| This floral shade is way to pretty for my workshop. |

|

| Removing the set screw. |

|

| A little of the old push 'n pull technique |

|

| Like Ruffles, it has ridges. |

|

| Yes, it's "green apple" scent. |

Note to self: future project - find a shapely, plastic woman's leg and make my own, fragile Christmas Story lamp to display in our front window. The wife will love it!

|

| Believe it or not, I've never had a manicure my whole life. Honest! |

After that, it was just a matter of reassembling everything I had taken apart, in reverse order. It's probably best to lay the pieces in order on your workbench rather than fling them randomly about like I did, resulting in a pissed-off Easter egg hunt. I fed the cable backwards through all the elbows until there was just enough to fit into the socket enclosure. All the various nipples threaded back in with their retaining nuts tightened.

I gently threaded the lamp in. Finally, the moment of truth, my friends.. (click)

|

| Blinded by the light, revved up like a deuce, another runner in the night!! - Manfred Mann's Earth Band |

There's nothing better than a nice book under the warm glow of a reading lamp...

Quick and Easy Shaker Drawer Fronts (Dodos vs Rabbits)

As part of my challenge to clean up all the loose ends around here, I'm attacking the project with renewed effort. To get back in action, I need to make four drawer fronts.

Initially, I was going with flat, recessed fronts. I even have them cut to size and sanded. The problem is, they simply look too plain. I wanted something a little more interesting.

|

| Plain, like Saltines without the salt. Boring. |

|

| An operation of absolute sawdust-spewing joy. |

Quick tip: When I have the tool set up and am making precise, repetitive cuts, I often make several extra pieces, if I have enough wood. It saves heartache later when, I inevitably pull some lame-brained move and screw up a piece (...which I did do).

On woodworking joinery, extinct terrestrial avians, and common Lepus currpaeums:

|

| Don't try this at home,... or at work,... or in a restaurant,... or in the shower. |

|

| A freshly prepared rabbet. |

|

| I'm just glad I didn't knock my beloved Bad Ass coffee mug off the bench. |

|

| I only took a little meat off my pinkie knuckle. |

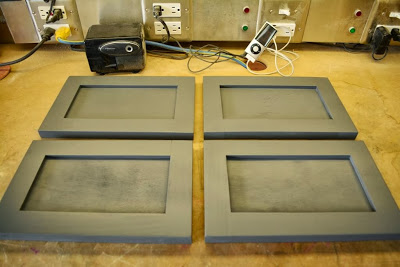

- That is some seriously dark primer. Painting these things white will mean more coats.

- In my zeal to get the panels in, and concentrating on setting my camera, I had lost focus and installed a couple of the panels backwards, rough, un-sanded side out.

- Idiot.

- On quick and easy: It was both, quick and easy but the many outfit changes (I'm a Grand Master of wearing solid color T-shirts) and the changes in lighting in these photos betray me. I picked away at this over several days, stepping out in the garage for a few minutes here and there between doing other stuff.

- Before mass producing the four fronts, I used the old Norm Abram's New Yankee Workshop trick of building a first pre-production copy. I worked out the problems and played with the technique before committing to building all of them. You'll see this mystery prototype in the background. It's assembled without glue, just the screws, but it's holding tight.

|

| Eyeballing the prototype piece on the actual project. |

Favorite DIY Stuff 2013 - Pt II

2013 Favorite DIY STuff: Molekine Notebook, Bench Cookie Work Grippers, DeWalt Self Leveling Laser Level, Kreg Jig Jr. Pocket Hole System

Read MoreFavorite DIY Stuff 2013 - PT I

Victorinox Swiss Army SwissTool, Red Wing Moisture Wicking Socks, Carhartt Nail Apron, Diablo Demo Demon Carbide Reciprocating Saw Blade

Read MoreBuilding the Ultimate Workshop Power Strip: More Power!!!

This technological terror is a hand crafted ULTIMATE garage workshop power strip.

Read MoreThe Great Debate: Hiring a Pro vs DIY (Replacing Swimming Pool Equipment Edition)

- A new cartridge filter to replace the aging DE filter (the big R2-D2 looking thing) so back-washing and dealing with that messy white powder is a thing of the past. Old leaky here has been a maintenance nightmare. It would need hundreds of dollars in replacement parts if we wanted to save it. A cartridge filter will reduce my maintenance time greatly.

- Replace the pool pump. The existing motor is doing fine, since the it was replaced a year ago (home warranty!!!) but, we expect to save about $700 annually in power consumption by upgrading to a modern, variable speed pump. Plus, the unit is tired and has air and water leaks.

- Adding a salt water cell. This is actually exciting. We are going to nearly eliminate our chemical dependency (and cost!!!!) by converting salt water to chlorine. Everyone I talk to who's made this conversion has loved it.

|

| No swamp. |

|

| Swamp. |

Homework: There's a neat article Marcie Geffner wrote last year for Bankrate.com, titled Remodeling Yeilds Rewards, Vexations where she compares my successful family room remodel experience to cautionary advice from the authors of Home Improvement For Dummies. I do their cautionary, contrasting point of view vs. my gung-ho, I-can-do-anything approach. Doing research, I found their website diyornot.com, which provides lots of info on DIY vs. hire. It's a very good site. I just get a vibe that it's pushing the hire direction a bit hard, especially with an apparent choice of advertisers directed towards for hiring contractors. Maybe I'm a bit sensitive because I love the do it yourself approach. Heck, I have ads for tools and materials on my site. - John

A Relaxing Labor Day Project: Underground Electrical

Even though I'd proclaimed it a no-project weekend, I started excavating the slab the equipment is sitting on. I thought I'd be nice and hopefully avoid the cost creep of having a pool tech digging at $80 / hour before dropping down a new slab. I dug it out pretty quickly.

|

| One of the many leaks dribbling away. |

Of course, it wouldn't be a ripping good DIY Guy project experience if it ended as neatly as that, would it? Nope. Remember Murphy's Law, my friends. I noticed this little gem of awesomeness:

|

| "Don't you call me a mindless philosopher, you overweight glob of grease!" |

conduit, wrapped in corrosion preventing rubber tape. Awesome. Guess what else?!!! There's cement covering it too. Oh, joyous day!! But that's not all; there's a thunderstorm bearing down on me. Sweeeeeeeeeeeet, now this is a holiday, my friends!!! So much for BBQ, it's going to be a carryout pizza night.

|

| The conduit on the left and the gounding box on top are brass, and in perfect condition. |

|

| Can you tell the new from the old? |

|

| 100 degrees and humid after the storm. It's not quite as fun as it sounds. |

I put all the wiring back exactly the way it was before. I recommend you don't mess around with electrical near a pool if you're not really comfortable with it. Seriously, hire an electrician. There's a whole section of code devoted to it.

|

| Generally, you don't see pools this color outside St Patrick's Day |

Installing a water heater shut-off switch

Last time, I mentioned I couldn't quite get to a water heater maintenance program without doing some repairs first. I figure step number one is to bring the electrical up to snuff. I decided to install a disconnect switch by the unit, so I don't have to trudge to the outdoor electrical panel every time I want to shut the unit off.

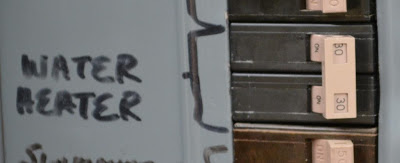

Before I could get going on this part, I had to replace the breaker. My predecessors had installed two, single pole breakers, rather than one double-pole 30 amp breaker. Not cool my friends.

AZ DIY Guy's Scary Warning - Electrical Edition: Don't mess with electrical, unless you know what you are doing. 120 volts of household current can kill you just as dead as much higher voltages, it just lets you suffer longer, and folks can still recognize you in your casket. Plus, electrical issues can do a heck of a job burning your house right to the ground. When in doubt, get a professional electrician. If you do the This project is a snap for someone who's trained; it shouldn't cost too much. Even if you know what you are doing, I recommend you work it like it's live, even if it's not. Research legal requirements in your area before making changes to your electrical system. Finally, don't take my word for this stuff, I might be some random idiot on the internet.

No. Not cool at all. Those are separate breakers. I picked up a breaker at Home Depot for about 13 bucks. It was an easy swap; just a matter of turning off the main breaker for a minute while I slipped the two originals, popped the new one in, and re landed the wires.

Of course it couldn't go perfectly. I noticed, for the first time that this particular circuit's wiring was aluminum. I hate that I have aluminum wiring. More on that later.

Cool. Very cool indeed.

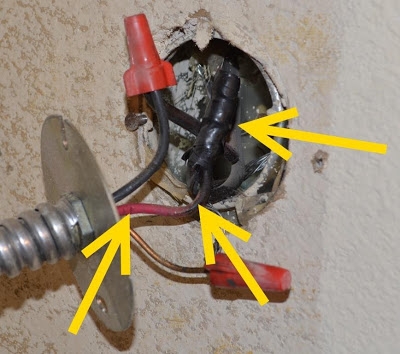

I turned off the new 2 pole circuit breaker and moved inside to open up the junction box to find,... a gob of black electrical tape, discolored wire, and nicked insulation (clockwise below). Not good signs.

Since I don't trust ANYTHING in this place, I like to do a quick check to see if the circuit is still live. Especially if there's some sketchy-looking wiring where I'm about to stick my fingers. Idiots could have easily landed one of the hot wires to the wrong breaker; it could light me up. No thanks. It's time to reach the Bat Belt for my trusty non-contact voltage tester.

.

.

Apparently, It's pretty serious.

Ahhhhh,... sweet silence. The circuit is dead.

This is scary. The wire nut inside the tape glob is completely destroyed. Worse yet, where is the rest of it? There were no fragments or pieces of more than half of it, not in the tape, not in the junction box. To me, this means some mental giant actually knew this was busted and wrapped it in electrical tape, rather than simply installing a new wire nut. This could burn a house down to save the effort of installing a cheap wire nut. Jackassery! I think it's especially unsafe in that it's aluminum to copper wire junction.

That's an identical, complete wire nut on the right.

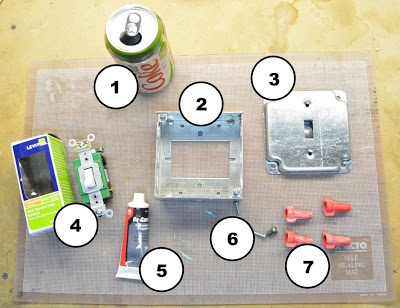

Back over to the workbench, I set up to prefabricate the switch assembly. Here's the stuff:

Diet Coke Lime The lime is important. I can't find the reference exactly, but it's in the National Electrical code somewhere,...promise.

Square Box Extension Ring. This will extend the in-wall box allowing for more room to fit the switch and wiring.

30 Amp, 2 pole switch I chose Leviton's extra heavy-duty spec-grade.

Anti-Oxidant CompoundThis gunk is required when you tie copper to aluminum wiring.

Screws: 8/32's to screw the window box, and one ground screw to ground it. (... to rule them all!)

Wire Nuts ..you know,...to nut wire.

I clipped the ears off the switch, so it would fit nicely behind the plate.

I pulled the existing 6/32 mounting screws out of the switch, since they're not needed here. Next, I stripped some new #10 copper wire and installed it behind all 4 termination screws, the line side (the "home run" to the breaker) on the black screws, load side (to the heater) on the brass.

No, the WD-40 and the big ol' bottle of blowin' bubbles are not necessary.

I like to put a wrap of electrical tape around the device, leaving a folded, courtesy tab for easy removal later.

Pop the cover on with the two short 6/32's (included with the cover) and we're ready to install.

The extension ring installs on the wall, screwed to the back box in the wall.

The stripped, bare copper and aluminum wires got a good bit of the anti-oxidization goop. Man! I wish we didn't have that aluminum wiring. At least it's only on a few circuits in the house.

All wired up and sealed in place. I slipped on a 90 degree flex connector, pulled fresh new wire to the heater, terminated it, and sealed everything up.

Flip the breaker and power it up. We should be in business, just in time for the next laundry cycle. Now I can shut the whole thing off whenever I'm finally able to drain it for maintenance.

Look good?

To check the voltage, I popped off the front cover, peeled out a piece of insulation, and exposed the internal wiring terminations for the the heating element. Careful, careful,.. 120 volts from both of the hot conductors to ground and 240 between them. Done!

240,...243.7, whatever it takes.

Next time kiddies, it's on to plumbing. I have to repair or replace that corroded, seized shut-off valve. I'll have to do some research on that one.