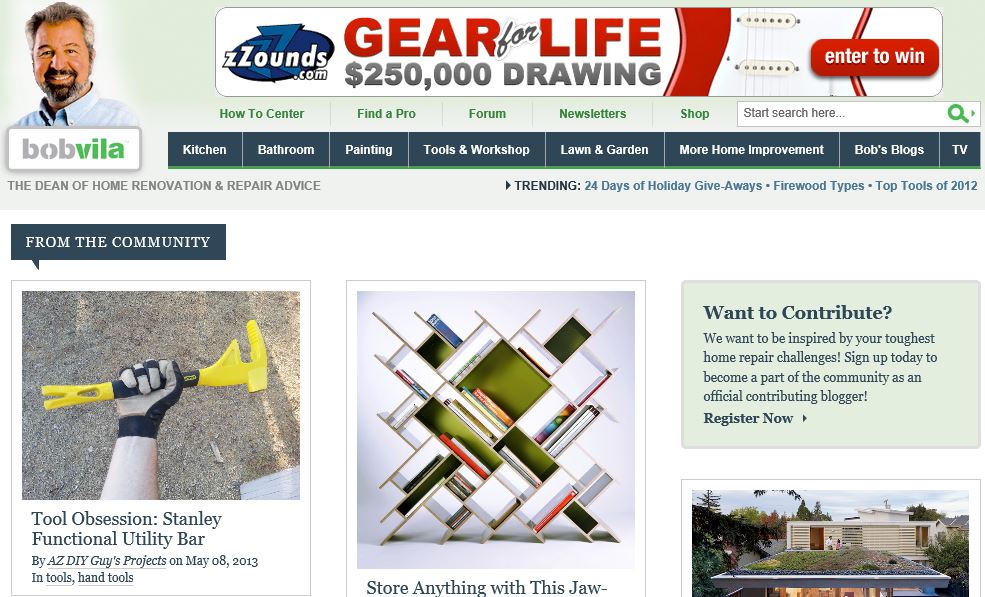

After a polite invitation from our HOA to promptly remove (demolish) our front door overhang, I decided that I needed to get something a little better than a 12" wonderbar and a too-heavy, sawed off sledge hammer to take into the fight. I considered the Dead On 18-Inch Annihilator Utility and Wrecking Bar versus the Stanley 55-099 FatMax Xtreme Fubar Functional Utility Bar

Choosing the FUBAR VS. The Dead-On Annihilator

A bit of research revealed that the users have reported quality issues with the Dead-On Annihilator. The design seems pretty good and it certainly looks wicked, but reports of slipping handles, claws snapping off, welds breaking and general failure of the cast-metal frightened me (and my wallet) off.

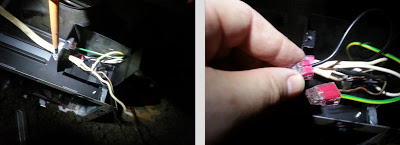

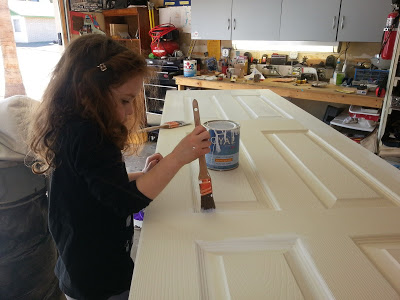

Photo: Courtesy of rockstar4960 - used with permission

"A 98 pound guy did this with a brand new tool, by banging it on a piece of wood. Yes, that is a weld. I guess they are 2-piece hammers. I expected it to be a 1-piece design. We'll see what their lifetime warranty is all about."

- rockstar4960

Most of the positive reviews I saw reflected on how mean it looks and an intent to use it as a defense weapon in the upcoming zombie apocalypse. Zombies, in a tool review. That's just stupid.

Just because it looks bad-ass and has a skull-head sticker, doesn't mean I'm going to take it within the 18" it would take to hit a zombie. You'll find yours truly wielding a trusty 3/4" conduit bender with a nice 36" long handle when it comes to repelling those brain-munching ghouls.

I went with the Stanley Functional Utility Bar. It's four pounds of forged-steel brutality. I liked the feel of it better in the store too; it just looked and felt more solid. I'm going to stop comparing the two, because I didn't take the Annihilator home and I can't review it in action. Just don't get hung up on the names; if you want some bad-ass street cred, the term "FUBAR" has some pretty tough roots itself, look it up.

From the manufacturer: Professional grade utility bar is a 4-in-1 tool for prying, splitting, board bending, and striking 1-piece forged steel for increased durability Textured grip for excellent comfort and control, even when wet beveled nail slot for pulling and prying nails. Limited lifetime warranty.

This isn't simply a review where set up ways to try the tool, just to share it with you. I purchased and took the FUBAR into actual battle in the demolition of our front porch overhang , a treacherous tunnel of ill-constructed lumber, nails, and hardware to lay waste upon. I brought along my sawed-off sledge, (Mjölnir) but it never got a chance to play. The FUBAR hogged all the carnage.

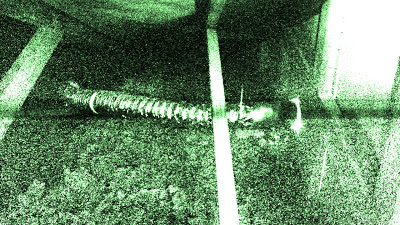

Destructive fury, pictured from (left to right):

THUNDER! and LIGHTNING!

I thought if I threw it, it was supposed to fly back into my hand.

As a demo hammer, it made short work of slaughtering latticework. I used the big gripping claw to rip and pull at it, the pry bar to pop it off the frame and break it down into strips. It also worked really well in twisting and ripping 2x boards off. It grabs ahold and bites in, hard.

The hammer was beefy and balanced to strike mighty blows to the hardware, loosening it up, even blasting it clean off at times. It was initially annoying that the claw is too thick to pry narrow gaps like a hammer, and that there is not a nail puller on the head. It's an old ingrained habit to quickly reverse a normal hammer to pull nails or pry with a claw.

Instead, the FUBAR has a forked pry bar, at the handle end instead of the head. After a little use, I got used to it being down there and was no longer annoyed. It probably makes the tool a lot stronger to keep the claw end so beefy. I found myself prying holding the top of the claw, in a T-grip fashion. It was comfortable and allowed good leverage. Now, I like it this way.

Nail pulling is easy. The hammer, with it's meaty heft, pops them hard from the reverse side. The combination of the forks and the pulling slot zaps them the rest of the way out quickly. Due to the hammer balance being a little weird, it takes a little more attention to hit the nails without bending them, versus a normal claw hammer, but if you connect squarely, the nails are going backwards in a hurry! I've seen others lament the curved pry bar being a wrist hazard for right-handed bashers, but it gave me no trouble whatsoever.

The good old pry and whack maneuver

I pounded, twisted, pried, and ripped the heck out of the structure. The FUBAR stayed with me as the primary tool of devastation. I bet the neighbors enjoyed me leaping up to pound the decking off the rafters like I was the Norse God of Thunder. With my hand at the base, just above the bent pry bar and on the rubber grip, I could deliver some serious leverage to my swings without worrying about the thing flying out of my gloved hand and hurtling through the front window.

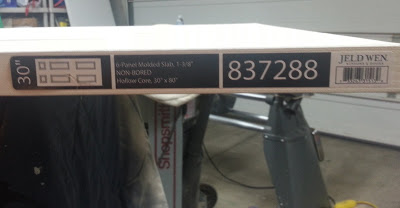

I did use the claw to pry a new board in to place a bit before shooting with the nail gun. It did it very well, but it's probably not best for finished surfaces (like facia) because it leaves some tooth marks. It would be great for framing though.

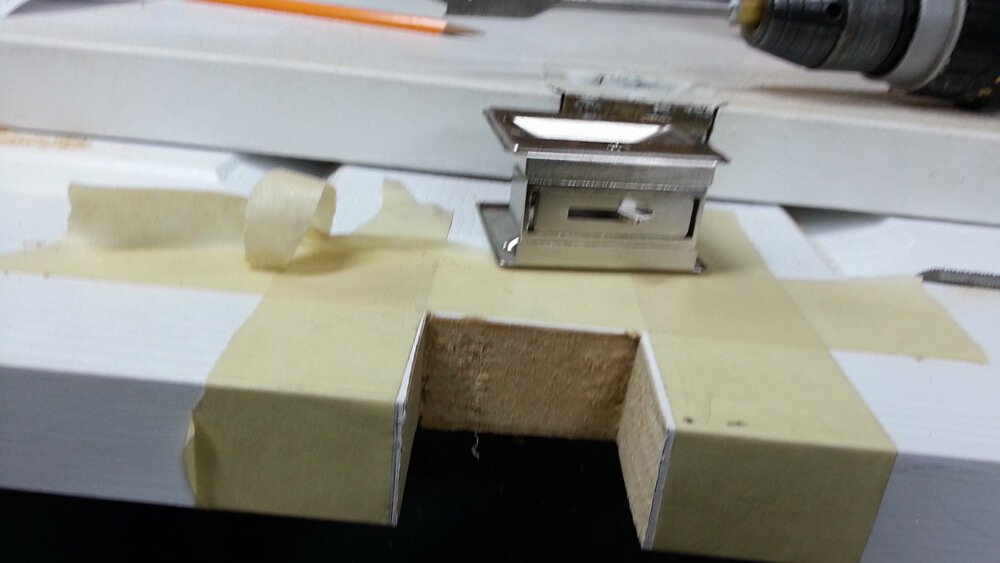

I discovered "makeshift vice mode", you can now call it a 5-in-1 tool Stanley!

This thing is a beast. Honestly, I abused it and only scratched the paint.

I probably shouldn't be doing this,... but it worked.

The verdict -

- This is a well-crafted tool of demolition madness. I heartily recommend it, for what it is supposed to be. It's not a framing hammer.

- I'd never try to install nails with it; it's too clumsy for precision work when my fingers are on the line. It's not a full size crow bar, not enough leverage.

- It's not a sledge hammer, heavy, but not that heavy. It is a tough, multi-function demo tool that does what it's supposed to. The only thing I didn't try was the drywall wrecking blade below the hammer head. Maybe I'll wait until Sweetie is at the hair salon and I'll take out a wall to report back to you fine readers.

- I do suppose it would do some serious damage to the zombies too,... if you want to get that close. I'll pack it as a back up when it gets that serious.

What are you waiting for? Get a Stanley 55-099 FatMax Xtreme Fubar Functional Utility Bar and wreck some stuff!

Note: This is not a sponsored post. I selected and purchased the tool myself.

UPDATE!!

I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image.